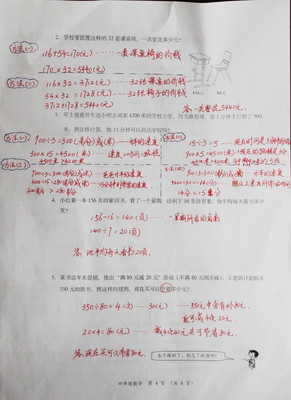

| 四.报告部分 全况检验 兹应中船保上海分公司委托,下列署名的验船师代表OCEAN P & I SERVICESLTD.于0000年8月8日及9日, 在上海港东昌装卸公司码头对“XXXX”轮进行了全况检验。 THIS IS TO CERTIFYthat the undersigned surveyor did, at the request of the ShanghaiBranch of China Shipowners Mutual Assurance Co. on behalf of OceanP & I Services Ltd., attend on board the M.V.“XXXX” at the wharf of Dongchang Stevedoring Company of ShanghaiHarbor on Aug. 8 & 9, 0000 for the purpose ofcarrying out a full condition survey to the ship. 全况检验分别于0000年8月8日0900至1530时,0000年8月9日0930至1330时进行。 The fullcondiiton survey was carried out in the period of 0900-1530 hrs onAug. 8, 0000 and 0930-1330 hrs on Aug. 9, 0000. 船舶概况 SHIP’S PARTICULARS 船 船名Name of Ship: 船 船籍港Port of Registry: 船 船舶呼号Official Number: 龙 龙骨安放日Date on which keel was laid: 制 制造日期Built in: 制 制造厂Built by: 船 船东Owner: 全 全长L.O.A.: 垂 垂线间长L.B.P.: 型 型宽Molded Breadth: 型 型深Molded Depth: 载 载重量Deadweight: 主 主机Main engine: S A.船舶证书及船级状况DOCUMENTATION 1. 该轮船主于0000年5月21日取得该轮所有权,加入中国籍。国籍证书编号为:HU 00000000。 有效期至0000年5月20日.Since May 21, 0000, the ship’s Owner has obtained the ownership ofthe ship, the ship’s nationality has been changed to be China andthe ship registered with Certificate of Nationality No.HU 00000000,valid until May 20, 0000. 2. 0000年6月,中国船级社对该轮完成了特别检验、坞内检验、尾轴检验、锅炉和蒸汽管检验。同时,按照SOLAS、载重线公约、防污染公约的要求,对各有关公约的证书进行了换证检验。Theship’s special survey, docking survey, screwshaft survey, boiler& steam pipe survey were carried out by CCS in June0000. In the meantime, the new statutory certificates were issuedunder the provisions of the International Convention for the Safetyof Life at Sea, the International Convention of Load Lines, 1966and the International Convention for the Prevention of Pollutionfrom Ships, 1973. 经查阅该轮的证书及检验报告等资料,该轮在进行了上述各项检验后未存在船级条件遗留问题。Uponexamination of the ship’s certificates, survey reports, etc. Nooutstanding recommendations were given after completion of theabove-mentioned surveys. 3.下列短期证书均于0000年6月15日签发,有效期均为0000年11月14日,全期证书尚待总部签发,全期证书的有效期为0000年6月14日。The following short termcertificates valid until Nov. 14, xxxx were all issued and the fullterm certificates are until June 14, xxxx are recommended to beissued by Head Office. 货船构造安全证书Cargo Ship SafetyConstruction Certificate (Form CSC(CHN)) No.SH000000; 货船设备安全证书Cargo Ship SafetyEquipment Certificate (Form CSE(CHN)) No.SH000000; 货船无线电安全证书Cargo Ship SafetyRadio Certificate (Form CSR(CHN)) No.SH000000; 国际载重线证书International Load LineCertificate (Form CLL(CHN)) No.SH000000; 国际防止油污证书International OilPollution Prevention Certificate (Form COP(CHN)) No.SH000000 4.起货设备Cargo handinggear: 下次年度检验日期为0000年12月, Date of next annual inspection: Dec. 0000 下次四年度全面检验日期为0000年12月。 Date of next quadrennial thorough examination:Dec. 0000 5.船级状况Class condition: 1)船级符号Characters of classification and class notations: 船体For hull ZCA Strengthened for heavycargo, Ice Class B 轮机For machineryZCM 2)上次特别检验日期Date of last specialsurvey: June 15, 0000 下次特别检验日期Date of next special survey: June 14,0000 3)上次坞内检验及螺旋浆轴检验日期 Date of last dockingsurvey/screwshaft survey: June 0000/June 0000 下次坞内检验及螺旋浆轴检验日期 Date of next docking survey/screwshaft survey:June 0000/June 0000 4)上次锅炉及蒸发管检验日期 Date of last boiler & steam pipesurvey: June 0000 下次锅炉及蒸发管检验日期 Date of next boiler & steam pipesurvey: June 0000 6. 该轮油类记录薄、已认可的稳性/装载资料均保留在船上。安全图、应变部署表、训练记录均使用了中文,并张贴在合理的位置上。Theship’s Oil Record Book and approved stability/loading informationwere kept on board. The safety Plan, Muster Lists and Record ofDrills, all expressed in Chinese language were posted in properplaces. B.检验查明 GENERAL CONDITION INSPECTED 1. 轻载水线以上的船壳板的外表面,70%面积分布有较严重的疤状锈蚀。轻、重载水线间的G、H列板最大锈蚀达24.1%,一般锈蚀为14%;Theboth side shell plating above light waterline was found to haveserious rust scales covering about 70% of total area. The shellplating, strakes G & H bet. Light &load waterlines were found corroded to the maximum about 24.1% ofthe original thickness, generally about 14%; 56-57肋位间及136-137肋位间的二条环带区域测厚结果显示部分范围舷侧板与船底板锈蚀严重,最大锈蚀达26.4%;The shell plating and bottom plating in the belts bet. FrmNos.56-57 & 136-137 were gauged and some of themfound corroded to the maximum about 26.4% of the originalthickness. 上甲板呈现严重锈蚀,最大锈蚀达25.2%,平均锈蚀达20%;The upper deck plating was found seriously corroded to the maximumabout 25.2% of the original thickness and average about 20%. 所有防腐锌块于0000年6月在坞内换新;Allanticorrosive zinc slabs were renewed in dock in June 0000. 船壳板及上甲板内侧面防腐塗层处于较好养护状态。Theinside anticorrosive coatings of shell plating and upper deckplating were found in fair maintenance condition. 2.货舱内所有主肋骨及其上、下端连接肘板未见明显的变形及损坏。油漆塗层90%有效。各水密横舱壁的根部呈现较严重锈蚀,其中第三、四货舱间横舱壁右舷根部穿孔,现设置水泥箱。Allmain frames with upper & lower brackets in allholds were found without apparent deformation &damage, and 90% of pain coating thereon in order. All watertighttransverse bulkheads were found seriously corroded at their bottom,among which the tweendeck bulkhead bet. Nos.3 & 4cargo holds corroded through at the std bottom and fitted withcement box. 第三冷藏货舱已改作一般货舱使用,舷侧及前后横舱壁的冷藏绝缘层仍完整。No.3refrigerated cargo chamber was converted into a general cargo holdand the insulation fitting on the side shell plating and fore& aft transverse bulkheads still sound. 3.各货舱钢质内底板仅有轻度凹陷,油漆塗层基本失效。各货舱内的污水井,包括盖板、滤网处于正常状况,抽吸效用试验正常。各货舱内的垂直扶梯,二层甲板开口处的安全防护装置均处于有效状态。舷侧木质自动护舷材基本完好。手提式货舱照明灯存放在桅屋。Thesteel inner bottom plating in all cargo holds was slightly indentedand paint coating thereon generally missing. The bilge wells withcovers & rose boxes in all cargo holds were foundin normal condition, and operating tested to satisfaction. Thevertical ladders in all cargo holds and the safety railing devicesaround tweendeck opening were found in efficient condition. Thewooden spar ceiling generally sound. The portable hold lights werestored in the masthouses. 4. 船级社验船师已于0000年6月在对该轮进行特别检验时,对所有压载水舱、燃油舱等进行了内部检查及水压试验。本次检验对第一压载舱(左、右)、第二压载舱(左、右)、第三压载舱(左、中、右)、首尖舱进行了水压试验,情况正常。各压载水舱的空气管、测深管及其护罩,水密门均处于正常水密状态。Allballast water tanks, fuel oil tanks, etc. Were internally inspectedand water head tested by classification society surveyor in Junexxxx during the ship’s special survey. At the time of this survey,No.1 D.B.B.W.T. (P & S), No.2 D.B.B.W.T. (P& S), No.3 D.B.B.W.T. (P,C & S) andforepeak tank were water head tested and found satisfactory. Theair pipes, sounding pipes with protective guards and watertightmanhole covers of all ballast water tanks were found in normalwatertightness. 5. 第1,2,3,4,5 钢质自动舱盖与0000年6月进厂进行过全面整修。橡胶水密封条全面换新,压紧装置、行走导轮大部分换新。本次经外观检查及冲水试验,情况正常。The MacGregor type of hatchcovers of Nos.1,2,3,4 & 5 holdswere thoroughly repaired in the shipyard in June 0000 and theirrubber packing all renewed, the securing devices and runningrollers mostly renewed. They were visually inspected and hosetested and found satisfactory. 6. 各货舱菌型机械通风筒普遍呈中等程度锈蚀,前桅屋顶部通风筒距桅屋顶0.5米处锈蚀穿孔。各通风筒防火挡板均处于正常关闭状态。Allmechanical mushroom ventilators for cargo holds were foundgenerally and moderately corroded. The ventilator on the top of thefore mast house was found corroded through at 0.5m off the roof ofthe mast house. The fire dampers of all ventilators were found inefficient condition. 7. 电动锚机、尾绞缆机、起货机绞车处于一般维护状态。安全护罩及基座情况正常。起重桅及吊货杆油漆塗层完好,情况正常。The electricwindlass, aft mooring winch and cargo winches were found in generalmaintenance condition, the safe covers & seats innormal condition and the paint coatings of derrick posts& derrick booms in good condition. 8. 艏楼甲板及上甲板上的小舱口、吨位开口,艏楼后端壁、桅屋及艉楼前端壁上的水密门处均有效水密关闭状态。Small hatches onthe forecastle deck & tonnage well on the upperdeck and watertight doors on the aft end bulkhead of forecastle,mast house and fore end bulkhead of poop were in efficientcondition. 9. 全船消防栓、皮龙、喷嘴均按防火控制图配置,处于正常使用状态。国际通岸接头设置在驾驶室内。All fire hydrants,hoses and nozzles were arranged according to the fire control planand found satisfactory. The international shore connection wasstored in the wheel house. 10. CO2固定灭火系统服务于机舱及货舱,使用说明张贴在CO2站室及驾驶台,下次CO2重量的称重日期0000年2月,下次系统畅通试验日期为0000年2月。Thefixed CO2 fire extinguishing installation for engine room and cargoholds were provided and the operating instructions were posted inCO2 station and wheel house. Date of next CO2 weighing and blowingthorough of system piping: Feb. 0000. 11. 应急消防泵设置在泵间,效用试验情况正常。The emergency fire pump fitted in pump roomwas operating tested and found satisfactory. 12.左、右舷开敞式机动玻璃钢救生艇处于良好维护状态,救生艇收放试验情况正常。吊艇钢丝0000年5月换新。气胀式救生筏4只定额总数为40人,最近检查日期为0000年6月。其余救生设备均完整无损。Theport & std open motor glassreinforced plasticlifeboats were found in good maintenance condition and loweringtested to satisfaction, the falls were renewed in May 0000. 4inflatable liferafts, capable of accommodating 40 persons in total,were serviced in June 0000. The other life-saving appliances werefound in good condition. 13. 泵舱内的机械及电气设备需进行整理、清洁,去除无关杂物。 The machinery installation& electric equipment in the pump room need to betidied, cleaned and useless things removed. 14. 急救及医疗设施和设备情况正常。First aid and medical facilities and equipmentappeared in order. 15. 主机为一台FIAT C75BS型柴油机。0000年6月第三、五缸组进行了吊缸检查,且十字头轴颈进行了喷镀,轴承换新,第一至六缸缸头及缸套检查情况正常。主机油泵凸轮轴磨损严重。其余主机及为主机服务的各系统运转情况正常。现使用的服务转速为98转/分(额定转速125转/分)。主机排水关绝热护套完整无损。查无完整的轮机日志。Themain engine was one set of Type FIAT C756S diesel engine. In June0000, No.3 & No.5 cylinder units were overhauled,and the crossheads metallized and bearings renewed. Nos. 1-6 cyl.covers and liners were inspected and found satisfactory. Thecamshaft of M.E. oil pump was found seriously worn. The remainingparts of the main engine and all systems serving the main enginewere found in normal running condition. The working revolution was98 rpm (the rated revolution: 125 rpm). The M.E. exhaust pipe waswell lagged. No complete set of machinery log book was kept. 16.“SCOTCH”辅锅炉一台,工作压力7kg/cm2,未设置高低水位报警,无自动停风安全装置。人工点火。0000年6月曾进行过水压试验和内部检查,现保护及绝缘外套,玻璃管水位计外观检查情况正常。废气锅炉已停止使用。 “SCOTCH” aux. boiler, one set,working pressure: 7 bar No high & lowwater level alarm system, no furnace draught loss safety systemwere fitted. The boiler was ignited by hand. In June 0000, the boiler washydraulically tested and internally inspected. The lagging and thewater level glass gauge were visually inspected and foundsatisfactory. The boiler was externallyinspected in normal working condition. The exhaust gas boiler wassuspended from service. 17.电动液压舵机效用试验情况正常。锚机间机旁操舵装置及尾楼艇甲板上的操舵装置均处于正常使用状态。舵机间与驾驶台的通信及舵机间内的罗经装置均处于正常状态。Theelectro-hydraulic steering gear was operating tested and foundsatisfactory. The auxiliary steering gear in the steering gear roomand hand wheel on poop deck were both found in normal workingcondition. The communication bet. steering gear room and bridge andthe gyro compass repeater in the said steering gear room were foundsatisfactory. 18.BV6M536型辅机二台,V6M536型辅机一台。二号辅机于0000年拆检,同时,整个辅机系统经调速性能试验合格,现系统运转正常。 Auxiliary engines, TypeBV6M536, 2 sets; Type V6M536, 1 set No.2 aux. engine wasoverhauled in 0000 and meanwhile the governors of all auxiliaryengines were functionally tested and found satisfactory. Now, thesaid installation was found in normal running condition. No sparenozzle of prime mover was provided. 19.总配电板、应急配电板及各分区配电板外观检查情况正常。查全船绝缘电阻记录,居住舱室照明电话绝缘电阻值在某些部位低于0.1Mr。Main& emergency switchboards and distribution boardswere visually inspected and found satisfactory. Upon examining therecords on the insulation resistances of the whole ship, theinsulation resistances of the lighting system in the accommodationspaces were lower than 0.1 Megohm at certain locations. 20. 分油机共五台,其中:Purifiers, 5 sets in total: #1、#2为DZY-50型,排量5000升/时 Nos.1 & 2 purifiers, Type DZY-50,output capacity 5000 L/hr; #3、#4为DELAVALPX309-25F型,排量6000升/时 Nos.3 & 4 purifiers, Type DELAVALPX309-25F, output capacity 6000 L/hr; #5为DELAVAL型,排量1500升/时。 No.5 purifier, Type DELAVAL, output capacity 1500L/hr. 上述#3,#4分油机待修理,现停止使用。机舱油污水分离装置于0000年6月进行了检查及水样检查。现处于正常工作状态。Theabove-mentioned Nos.3 & 4 purifiers were suspendedfrom service for waiting repair. Oily-water separating equipmentfor machinery space bilge was inspected and sample examined in June0000. Now, the said equipment was found in normal workingcondition. 21. 海水进出口阀共61只,于0000年6月在坞内进行了检查,拂磨,现处于正常工作状态。Sea water inlet& outlet valves, 61 pcs in total, were inspectedand repaired by means of grinding in dock in June 0000. Now, thevalves were found in normal working condition. 22. 机舱风、油紧急切断装置,机舱棚烟囱、通风筒关闭装置效用试验正常。The emergency shutting offdevices of E.R. ventilating fan & fuel oil systemand the closing appliances for ventilators and funnel annularspaces leading to E.R. were functionally tested and foundsatisfactory. 23. 机舱清洁状况一般。污油水的淤积处于正常状态。The engine room looked in general finecondition and the bilge was accumulated in satisfactorycondition. 24. 机舱CO2固定灭火系统,46升大型泡沫灭火机及小型手提式灭火机均处于正常状况,符合防火控制图的配备要求。In E.R.,CO2 fixed fire-extinguishing installation, 46-ltr large froth fireextinguisher and portable fire extinguishers were all foundsatisfactory and fitted in places in compliance with the firecontrol plan. 25. 食品冷冻机组工作状况欠佳。船东已计划在近期内换新。冷库内应急求援装置经实效试验情况合格。The provisionrefrigerating installation was found in poor working condition andthe Owner has intended to renew it soon. The emergency warningdevice in reefer space was functionally tested and foundsatisfactory. 26. 驾驶室整洁。航行设备包括:The wheelhouse was clean. The navigationalequipment includes: 1) KGP-911卫星定位仪,一台。KGP-911satellite locator, 1 set; 2) ADF-2200测向仪,一台,0000年3月16日经误差校准。ADF-2200 direction finder, 1 set;Its calibration was checked on March 16, 0000. 3) 磁罗经,0000年3月16日经误差校准。Magnetic compass, 1 set; Its deviation waschecked on March 16, 0000. 4) ANSCHUTZ-KIEC电罗经一台。ANSCHUTS-KIEC gyro compass, 1 set; 5) JMA-8253-7及MR-1200E雷达各一台。JMA-8253-7 & MR-1200Eradars, 1 set each; 6) TF-733气象传真一台。TF-733 weatherfacsimile, 1 set; 7) ITT STR-65 VHF电话一台。ITTSTR-65 VHF radiotelephone, 1 set; 8) SZS-3测深仪一台。SZS-3 echosounder, 1 set; 9) XZC2-2数字气象仪一台。XZC2-2digital meteorograph, 1 set; 10) 应急示位标。SARSET E.P.I.R.B., 1set. 适用该轮航班区的海图、94年版潮汐表及最新版的航路指南、航行通告均已配备。The chartsfit for the ship’s sailing area, tide tables, up-to-date sailingdirections and notices to marines were all provided. 27. 无线电报设备处于正常使用状态,包括: The radiotelegraph stationincluding the following installations was found satisfactory: 1) ELETROMEKANO S1250主发信机ELETROMEKANO S1250 main transmitter; 2) ITT ST86B应急发信机ITT ST86Bemergency transmitter; 3) AK5023自动拍发器AK5023 automaticalarm signal keying device; 4) R5001主受信机R5001 mainreceiver; 5) M125应急收信机M125 emergencyreceiver; 6) 单边带Single sideband; 7) CB-1B自动报警(500KHz) CB-1Bauto alarm (500KHz); 8) DC-300D自动报警(2182KHz)DC-300D auto alarm (2182 KHz); 9) TRP-5001备用发信机TRP-5001reserve transmitter. 此外,蓄电池组处已正常维护状态,有关出版物已配备。Besides, the batterieswere found in satisfactory maintenance condition. The relevantpublications were provided. 28. 厨房、食品库清洁整齐,完整无损。The galley and the provision locker were foundclean and in good condition. C. 综述 GENERAL CONDITION 该轮船年龄已达33年。船体,尤其是上甲板锈蚀状况严重,局部范围已超出CCS船级社的规定。据了解,该轮0000年6月完成船级特别检验项目,下次特别检验间隔期已定为二年。Theship is 33 years old. The ship’s hull, especially upper deckplating, was found seriously corroded and partial locationscorroded over the allowance limits set forth by the ChinaClassification Society. Upon investigation, the last class specialsurvey items were completed in June 0000, and later on 2-yearlyinterval special survey will be undertaken. 在全况检验期间,下列缺陷被发现,并以备忘录通知船长:During the full condition survey, thefollowing defects were found and advised in a memorandum to theship’s Master: 1. 艏楼甲板上右侧空空气管在根部烂穿应予割换;Stdside air pipe on forecastle deck corroded & holedat heel to be cropped & renewed. 2. 前桅屋平台中部的通风筒从根部烂穿0.5米高应予割换;Ventilator on the center of platform offore mast house corroded & holed at height of 0.5mfrom bottom to be cropped & renewed. 3. 艉楼前舱壁左、右水密门上的水密盖严重腐蚀应予换新;Watertight covers above the port& std watertight doors at fore bulkhead of poopseriously corroded and detached to be renewed. 4. 第四、五货舱与艉楼间桅屋处的左舷舷墙严重倾斜应予开航前修妥;Port bulwark in way of the mast housebet. No.4 & No.5 holds and poop seriously inclinedto be repaired before the ship’s departure. 5. 泵间内的机器和电气设备应予整洁。Machinery& electrical equipment in pump room to be cleaned& tidied and useless things to be clearedoff. 在整个检验过程中,船长、轮机长及有关船员均给予良好的合作,且上述书面通知的缺陷第一至四项船东已作永久性修理。During thewhole period of this survey, the ship’s Master, Chief Engineer andthe crew members concerned all gave very kind co-operation. And thedefects in the above-mentioned items 1-4, which were advised in amemorandum, were permanently repaired by the Owner. 制造中缺陷 应“XXXX”轮船东申请,于0000年5月5日及以后诸日在上海港对该轮船体及设备、轮机及电器设备等的损坏项目及制造中的缺陷进行了检验,情况如下: THIS IS TO CERTIFY that, at the request of the Owner of the M.V.“XXXX”, the undersigned surveyor did attend on board the said shipin Shanghai Harbor on May 8, 0000 and subsequent dates, for thepurpose of carrying out a survey to the damaged items and thedefects in manufacturing of the ship’s hull, outfits, machinery andelectrical equipment. 一.船体及设备部分 I. HULL AND OUTFITS 检验查明 Found: 1. 所有露天甲板货舱盖在未扣紧的情况下,舱盖的钢板已和舱口围板水平桁相接触,这样已无法将舱盖的密封橡皮压紧。All steel hatchcovers on weather deck, the edge of cover plates would come intocontact with the horizontal flats even with the clamping devicesbeing nor tightened, thus preventing the rubber gaskets from beingtightly pressed. 2. 露天甲板货舱盖的油路胶管太长,有碍货舱盖的顺利启闭。All steel hatch covers on weather deck,the hydro-pressure rubber oil pipes excessive in length, hinderingthe hatch covers from being easily opened or closed. 3. 艉左、右淡水柜的注水管和空气管现合用一根管子,不妥。Port and std stern F.W. tanks, a commonpipe was found to be used both for filling and air-relieving. 4. 室内走廊楼梯踏步胶皮五处脱落。Stair in theinterior alleyway, rubber mats of 5 steps detached. 5. 餐厅地板塑料贴面约3平方米脱落。Plasticflooring in saloon detached over an area about 3 m2. 6. 桅室门挂钩漏装四处,位置不妥三处。Mast housedoor hooks, 4 omitted from A38, A37, A35 and A27; and 3 improperlypositioned in A28, A29 and KK-7. 7. 厕所围壁漏水。The boundary platingof lavatory A-11 leaking. 8. 艏楼及端壁一水密门和邻近的货舱通风管道门不能同时开启。The opening of one W.T. door in the aftbulkhead of forecastle would interfere with the opening of oneadjacent cover plate for the ventilating port. 9. 艏部导缆孔的圆钢端部焊缝裂开。Stiffeningbar of one mooring pipe on forecastle, end welds broken. 10. 乒乓球室内地板敷料裂开。Deck coveringsin Ping Pong room badly cracked. 11. 所有起货设备地令选用型式不当,有下列缺陷:Alldeck eyeplate of cargo lifting gear unfit for service due toinadequate choice of type. The existing type was found to have thefollowing deficiencies: 1) 该型式的地令和甲板的焊缝无法作封闭的周围焊,焊缝端部有应力集中,易裂开。welds connecting the eyeplatesto deck plating could not be carries around and closed at ends, andends of welds liable to be subject to concentrated stress andcracked; 2) 地令和甲板间有空隙,内部易积水且无法保养。Excessive clearances left between theeyeplates and deck plating, hindering normal maintenance, and wateris liable to accumulate. 12. 所有起货设备羊角选用型式不当,强度不符合要求,现已有四只断裂。All cleats of cargo lifting geardeficient in strength due to inadequate choice of type, 4 werefound broken. 13. No.10起货机变速器手柄不能在原设计位置固定,且手柄已变形。Clutch gear control handle on No.10cargo winch bent, and the handle could not be fixed at designedpositions. 14. 驾驶甲板左舷红灯的灯座挡水板太低,致使积水溢出,污染外板油漆。Port side sidelight housing onbridge deck, the shipside flange bar insufficient in height;accumulated water would easily overfow, liable to stain thepaintwork down below. 15. 部分甲板流水孔位置不妥,致使甲板有积水,具体部位如下:Part deck scuppers improperlypositioned, causing water to accumulate on decks: 1) 主甲板No.4舱后左右两边Port and stdsides abreast No.4 hatch aft on main deck; 2) B层后甲板前部左右两边Port and stdsides forward on B aft deck; 3) 驾驶台左右两边Port and std sideson bridge. 16. 部分甲板流水孔位置不妥,致使甲板有积水,具体部位如下:Part scuppers at the inside ofcompartments improperly positioned: 1) 1 scupper in A20 portforward; 2) 1 scupper in A-11 portforward; 3) 1 scupper in A10 portforward; 4) 1 scupper in bath room on Aaft deck; 5) 1 scupper in lavatory on Aaft deck; 6) 1 scupper in Rm.B23; 7) 1 scupper in Rm.B23; 8) 1 scupper in bath roomB17. 17. 所有二层舱盖滚轮油嘴位置不妥。All greasenipples on the rollers of tweendeck steel hatch covers improperlypositioned. 18. Nos.1,2,3,4大舱的通风管道出口水密盖的橡皮填料损坏。Rubber gaskets on the covers ofventilating ports for Nos.1,2,3 & 4 holdsdeteriorated. 19. 水密门橡皮损坏总长约20米。Rubbergaskets on the W.T. doors deteriorated over an aggregate lengthabout 20m. 20. 舱盖水密橡皮损坏约50米。Rubbergaskets on the steel hatch covers deteriorated over an aggregatelength about 50m. 21. 舷窗水密橡皮损坏约50米。Rubbergaskets on the side scuttles deteriorated over an aggregate lengthabout 50m. 22. 由拉手拉气笛的钢丝转弯太多,经常卡住。Haulingwire for operating the whistle seized frequently due to excessivebends in the line. 23. A20室内通风管有漏水情况。Theventilating duct in room A20 leaking water. 24. B9室内天花板漏水。Overhead ceilingin room B9 leaking water. 25. A20室内壁板(在方窗角处)裂缝。Partitionplating in room A20 cracked in way of the corner of one squarewindow. 26. 第四舱处舵右舷墙有10米处焊缝裂开。Welds inboth port and std side bulwarks abreast No.4 hatch cracked at 10locations. 27. 第五舱测量管弯头太大,量水尺放不下。No.5hold bilge sounding pipe improperly arranged, and unfit for takingsoundings. 28. 艉双层底水柜测深管位置不妥。Soundingpipes of aft D.B. tanks improperly arranged, and unfit for takingsoundings. 29. 消防皮龙箱玻璃破碎共八块。8 pcs ofwindow glass of the hose boxes broken. 30. B25,B26,B27室内天花板漏水。Overhead ceiling in rooms B25, B26 and B27leaking water. 31. 驾驶两边的移门和门框相擦,开启困难,门挂钩损坏。Port and std side doors (sliding type) ofbridge house seized by door frames, difficult to operate, and doorhooks damaged. 32. 驾驶室后门挂钩座因固定在隔热物上,致使固着强度不足而脱落,此外,尚有D12,E1,E4,C1,B38,A1,A10,A11,A20及A21左右走廊门的挂钩有类似缺陷。Aftdoor of bridge house, the door hook dropped due to the hook beingattached to the insulation on boundary plating; similar defectswere found to door hooks of rooms D12, E1, E4, C1, B30, A1, A10,A-11, A20 and A21. 33. C22右,D19左右,B43左,A21右后走廊门的自动开闭失灵。Self closing devices of thefollowing alleyway doors out of order: C22 std, D19 port and std,B43 port, A21 std aft. 34. 第二舱前吊杆架处,固定吊钩用的令圈位置不妥。Onedeck ring plate for securing the cargo hook in way of No.2 forwardderrick strut improperly positioned. 35. A层甲板左走廊后门损坏。Aft door ofport alleyway on A deck damaged. 36. D11厕所及D层左厕所的马桶坐圈各一只损坏。W.C.seats broken, one each in lavatory D11 and in port side lavatory onD deck. 37. 驾驶台前方固定式的窗在室外一面擦洗不便。Thefixed type windows at the front side of bridge inconvenient forcleaning from outside. 38. D层甲板走廊左后门打开后不能固定。Aft doorof std alleyway on D deck could not be secured in openedposition. 39. 尾垃圾箱底盖活页损坏。Bottom flap ofrefuse container at stern of ship damaged. 40. 第一、二舱右边舷墙及艏楼右前部舷墙内陷,局部焊缝裂开(据该轮船长告称系受浪击所致。)Std side bulwark platingabreast Nos.1 and 2 hatches and std forward bulwark plating onforecastle deck set in, and part welds broken. (attributed to seadamage as stated by the Captain). 41. A19室窗口下的内壁板损坏。Insidepanelling underneath the window in room A19 damaged. 42. B41室洗脸盆破损。One wash basinin room B41 broken. 43. C9,D11,D9。E3,B31室内镜子水银脱落。The tinfoil paper of mirrors in rooms C9,D11, D9 E3 and B31 deteriorated. 44. C层甲板客厅门外楼梯踏步防滑橡皮条一处脱落。Rubber mat of one step of the stair outsidethe saloon on C deck detached. 45. C1室内椅子的两个挂钩和五只凳脚垫套损坏。2securing hooks and 5 leg shoes of the chairs in room C1damaged. 46. C1室内拉门的下面滑轮脱落。Bottomrollers of the sliding door of room C1 dropped. 47. A1室内移动把手损坏。Sliding doorhandle of room A1 damaged. 48. DP2,DP3。DP4室内的冷藏管路未包绝缘物。Insulation lagging of cooling pipes in roomDP2, DP3 and DP4 omitted. 49. 物料间五个木柜损坏。5 wooden boxedin store room damaged. 50. C1室内船钟不走。One clock in roomC1 out of order. 51. 30室内桌腿和椅子腿裂开。Legs of thetable and chair in room B30 cracked. 52. A10室的门损坏。Door of room A10damaged. 53. 救生艇物料箱盖无水密橡皮圈。Rubbergaskets omitted from the covers of all boat-equipment boxes. 54. 机舱棚内在靠近C13室处有一根污水管子漏水。Onescupper pipe in engine room casing adjacent to room C13leaking. 55. 罗经甲板上通风道室顶部漏装落水管。Onecompass deck, one scupper pipe leading from the top of ventilatorroom omitted. 56. No.4舱右后通风筒和主甲板的焊缝裂开。Weldsconnecting the ventilator to main deck at std aft side of No.4hatch broken. 57. 各露天甲板舱口盖渗水及内部凝水导致甲板上出口处(每舱口后端左右个一只)无防止海水倒灌设施。All drain pipe outletsfitted on the aft ends of horizontal flats (one pipe each on portand std sides for each hatch) for draining off the condensed andinfiltrated water from the hatch covers, unprotected from ingressof water. 58. 驾驶台的右门塑料贴面板及C甲板走廊塑料贴面板裂开。Plastic facings on the bridge house stddoor and on the side bulkheads in alleyway on C deck cracked. 59. No.2,No.3,No.4舱舱盖的开关箱变形(据该轮船长告称系受浪击所致)。Covers of control boxes usedfor operating Nos.2,3 & 4 hatch covers deformed.(Attributed to sea damage as stated by the Captain) 60. No.4舱左舷带缆孔损坏。Port sidemooring pipe abreast No.4 hatch cracked. 61. 厨房间抽风筒在下雨或甲板上浪时要积水。Ventilating port for galley liable to be subjectto ingress of water during raining or shipping water on deck. 62. 艉部导缆滚轮位置不妥,带缆时缆绳需经过方角的船尾部分,缆绳极易损坏。Aft mooring checks improperlypositioned, causing the mooring lines to pass around the sharpcorner of stern, thus the mooring lines would be most likely to besubject to chafing damages. 63. 室外甲板敷料有些地方有锈水泛出。计有:B层约4平方米,C层约9平方米,D层约12平方米,E层约4平方米,顶层约62平方米。Exteriordeck coverings were found to show signs of rusting, about: 4m2 on Bdeck, 9m2 on C deck, 12m2 on D deck, 4m2 on E deck and 62m2 on topdeck. 64. C19 室内抬子抽屉损坏。One tabledrawer in room C19 damaged. II. 轮机部分MACHINERY 1. 主机透平增压器的润滑油过滤器只有一只单联滤器,航行时不能清洗。Lub. oil filter for main engineturbo-superchargers incapable of being cleaned during navigationbecause only one set was fitted. 2. 主润滑油泵出口至各分路管上没有调节各分路润滑油压力的调节阀。Lub. oil pressure in branch pipesincapable of being regulated due to no regulating valves beinginstalled in branch pipes from the output side of main lub. oilpump. 3. 第1,2,3,4,5,6道中间轴承座漏油严重。Nos.1,2,3,4,5 & 6intermediate shaft bearing seats leaking oil seriously. 4. 主机第二号透平增压空气冷却器盖板的垫片破裂。Aircooler for main engine No.2 turbo-supercharger, the cover gasketbroken. 5. 螺旋浆经潜水员探摸有严重的空泡腐蚀(详见潜水员探摸报告)。Propeller blades pitted seriously dueto cavitation erosion. (see diver’s report) 6. 由空气瓶至各柴油发电机组的分路管路上没有截止阀。Nostop valves installed in branch pipes from air vessels to eachdiesel generating set. 7. 三座柴油发电机的原动机的淡水冷却系统均无放水旋塞。Fresh water cooling systems for threediesel-generating prime movers, no drain cocks being fitted. 8. 第一号柴油发电机的原动机的空气启动操纵阀杆断裂。Airstarting control valve spindle of No.1 diesel generator prime moverbroken. 9. 第一号柴油发电机的原动机第四缸组曲柄箱刀门有穿孔砂眼。Crank case door of No.4 cylinder unit ofNo.1 diesel generator prime mover was found to have through sandholes. 10. 三座柴油发电机的原动机的喷油嘴7只损坏。7 pcsof fuel injector of three diesel generator prime moversdamaged. 11. 燃油副锅炉和废气锅炉的安全阀均漏气。Allsafety valves of oil-fired aux. boiler and exhaust gas boilerleaking. 12. 副食冷藏用的第一和第三号压缩机的控制系统失灵。Control systems of Nos.1 & 3compressors for the refrigeration of food provisions out oforder. 13. 三座发电机组的手摇润滑油泵因装置不当,无法使用。Lub. oil manual pumps for three generatingsets unfit for use because of unproper arrangement. 14. 有下列各泵的轴封损坏:Following shaftseals damaged: 1) 主机第一号油水泵Main engine No.1sea water pump; 2) 柴油发电机组第一号淡水冷却泵No.1 freshwater cooling pump for diesel generating sets; 3) 废气锅炉的第一号和第二号循环水泵Nos.1& 2 circulating pumps for exhaust gas boiler; 4) 第一号卫生海水泵No.1 sanitary seawater pump; 5) 空调用的海水冷却水泵Sea water coolingpump for air conditioning; 6) 日用热水循环泵Daily hot watercirculating pump. 15. 淡水驳运泵至锅炉水舱管路上的截止阀失灵。Stopvalve in the piping between fresh water transfer pump and boilerfeed water tank out of order. 16. 空调系统各阀均发现漏气。All valves ofthe air conditioning system leaking. 17. 主机喷油嘴冷却水系统的自动控制系统失灵。Auto-control device for fuel injector coolingwater system of main engine out of order. 18. 主机曲轴箱的油雾探测器损坏。Oil mistdetector for main engine crankcase damaged. 19. 2台主空气压缩机的自动控制系统均失灵。Auto-control devices for two main aircompressors all out of order. 20. 右主空气瓶至主机柴油发电机组的输出阀均发现漏气。All output valves on the std main airvessel to main engine and diesel generators leaking. 21. 应急空气压缩机的离合器不能使用。Clutch ofthe emergency air compressor out of order. 22. 主机活塞冷却水柜里面油漆脱落。Insidepaintwork of main engine piston cooling water tank peeled. 23. 主机淡水冷却水的膨胀水柜里面油漆脱落。Insidepaintwork of fresh cooling water expansion tank for main enginepeeled. 24. 尾轴冷却水的回水管在焊接法兰处渗漏。Tailshaft cooling water return pipe leaking in way of the weldedflange. 25. 主机消音器的落水管有一段管子破裂。Onesection of drain pipe for main engine silencer broken. 26. 由废气锅炉至燃油副锅炉的蒸汽管在一焊接处渗漏。Onesteam pipe connecting the exhaust gas boiler to oil-fired aux.boiler leaking in way of the weldes flange. 27. 前气笛的空气减压阀渗漏。Air reducingvalve for fore whistle leaking. 28. 鱼肉冷藏间F12进水管在通过蔬菜间一段均无绝缘材料敷设。The insulation laggings omitted fromthe F-12 inlet and outlet pipes for fish and meat refrigeratingroom, where passing through the vegetable room. 29. 左机舱门的绝缘材料脱落。Insulation onengine room port side door dropped. 30. 舵机舱振动严重因引起下述项目损坏:Followingitems damaged due to serious vibration in steering gear room: 1) 应急消防泵的原动机的排气管振裂Exhaust pipeof the primer mover of emergency fire pump broken; 2) 舵机油泵的补充油管振裂。Supplementaryoil pipe of steering gear oil pump broken; 3) 舵机控制系统的一根油管振裂。One oil pipein the control system of steering gear broken; 4) 艉部左右淡水泵舱舱壁振裂漏水。Plating ofstern port and std fresh water tank cracked and leaking. 5) 绞缆机的电动机的控制箱内电阻脱落。Resistorsin the motor control box for warping winch disconnected. III. 电气设备部分 ELECTRICAL EQUIPMENT 1. No.1,No.2,No.3三台发电机激磁滑环接缝间隙太大,最大约2.5mm,使发电机运转不正常。Slip ring ofNos.1,2 & 3 generators excessive in clearnace, themax. clearance about 2.5mm. (see photo 1 ) and it caused thegenerators working abnormally. 2. No.3发电机激磁滑环有明显缺陷。Slip ringsof No.3 generator were found to have significant surface defects.(see photo 2) 3. 主机No.1润滑油泵电动机接线盒内有锈斑。No.1lub. oil pump motor of main engine, the inside of terminal boxrusted. 4. 主机No.2润滑油泵电动机接线盒内有锈斑。No.2lub. oil pump motor of main engine, the inside of terminal boxrusted. 5. 主机盘车机电动机接线盒内有锈斑,并其控制箱内指示灯不亮。Turning gear motor of main engine, theinside of terminal box rusted and the pilot lamp of its control boxfailed. 6. 副锅炉自动控制系统其燃油低温报警部分,高低水位报警部分及蒸汽高压报警部分工作均不正常;打风电动机的电缆损坏。Auxiliaryboiler auto-control systems, the alarms for fuel oillow-temperature, high and low-water levels and steam high pressureabnormal in operation; Feeding cables of the blower motor damaged. 7. 机舱通风机控制箱(P2-1)内主接触器线圈烧坏。Main contactor coil in the control box(P2-1) for engine room ventilating fan burnt. 8. No.1,No.2伙食冷藏机润滑油低压开关工作不正常。Nos.1 & 2 provisionrefrigerating compressors, the lub. oil low-pressure switches outof order. 9. No.1柴油发电机润滑油低压保护装置的电缆损坏。Cables of lub. oil low-pressure protectivedevices for No.1 diesel generator damaged. 10. 左右燃油沉淀舱液位发信器工作不正常。Port andstd oil fuel settling tanks, the transmitters of oil levelindicators abnormal in function. 11. 主机透平增压器的回油观察灯安装不合适。Thelighting for lub. oil sight-flow glasses of main engineturbo-superchargers improperly positioned. 12. 第二舱双杆平行电动机的接线盒与机壳之间连接焊缝裂开。Cargo winch of starboard gallows typeboom of No.2 hatch, the welded seams connecting the terminal box tothe motor frame cracked. 13. 第二舱右双杆平行吊电动机的接线盒变形(编号067568)。Cargo winch of std gallows type boomof No.1 hatch, the terminal box cover of winch motor (serialNo.067568) deformed. 14. 第二仓前右起货机电动机的接线盒内有积水。Terminal box of std forward cargo winch of No.2hatch leaking, with water accumulated in the box. 15. 应急照明蓄电池上下排间间距太小,影响维修保养。Space between the top and low rows ofemergency lighting batteries inaccessible for maintenance due tolimited spacing. 16. 配膳室烧水炉电热丝烧断。Heatingelements of water cooking boiler in pantry burnt out. 17. 第五舱左前方将军柱上的一只甲板照明灯的灯架损坏。One flood lamp bracket on the post at portforward side of No.5 hatch fractured. 18. 起货机的电动机控制箱室、锚机电动机控制箱室、通风机电动机控制箱室和冷藏机及空调控制箱室均没有铺设防滑和耐油的绝缘地毯。Oil andslip-resistant non-conducting mats omitted from the control boxrooms of cargo winches, windlass, fan motors and refrigerating andair-conditioning machinery. 19. 起货机的电动机控制继电器U11和U12损坏各二只。4control relays for cargo winch motors damaged (2 each of U11 andU12). 20. 日光灯镇流器共22只与该轮电站频率为60Hz不符。22 flouracent lamp ballasts (50Hz, 220V, 20W) unfitfor ship’s net work frequency (60Hz). 21. 主机盘车机的电动机移动控制器的电缆损坏。Theflexible cable of portable remote control pushbutton for the motorof M.E. turing gear damaged. 22. 移动抽水泵电动机其频率为50Hz,与该轮电站频率为60Hz不符。Motor (50Hz) of the portable bilgepump (V010, serial No.0212303/00333) unfit for the ship’s net workfrequency (60Hz). 23. 驾驶室自动电话及机舱控制间直通电话的铃声均太轻。The sound of telephone bells of theauto-telephone in wheel house and of the direct two-way telephoneat the engine room control station inaudible. 24. 冷藏机和起货机的电动机的控制箱内均无接线图或原理图。Wiring and schematic diagrams omittedfrom the control boxes for the refrigerating machinery and cargowinch motors. 25. 厨房照明电缆一根损坏。One lightingfeeding cable in galley damaged. 26. 舵角指示器现从照明分电箱L-9-19供电,不妥。Rudder angle indicator improperly fed fromthe lighting distribution box (L9-19). 27. 烟囱吸灰装置的电动机,现从照明分电箱供电,不妥。The motor of funnel soot blower improperlyfed from lighting distribution box. 28. 主发信机的整流器A3A1损坏。RectifierA3A1 of main radio transmitter (S 1250 serial No.71200-1)damaged. 29. 无线电充电系统电源变压器烧坏一只。One powertransformer (440/220V, AC, 60Hz) of charging facilities for radioequipment burnt out. 30. 广播系统扩大机的功率放大管损坏一只。Onepower tube (RCA-40411) of the ampilifier of broadcasting systemdamaged. 31. 艏艉对讲机喇叭的罩壳均损坏。Both casingsfor the two-way loudspeakers on the forecastle and poopdamaged. 32. 报房工作椅没有固定在地板上的拉攀。Workingchair in the radio room short of weather fastening fittings. 33. 机舱内计程仪复示器指示不正确。Theindication of log repeater in engine room incorrect. 34. 据船方告称并查阅航海日志,电磁式计程仪工作不正确。Electro-magnetic log abnormal in working.(alleged by ship’s Caption and confirmed with deck log book.) 35. 舵机房陀罗罗经复示器安装位置不妥,无法对复示器进行调整。One gyro repeater in steering gear roominacceddible for adjusting due to imporper position. 36. “B”雷达工作失灵。“B”radar out oforder. 要求/建议 Requirements/Recommendations: 应修妥To be remedied. 应修妥To be remedied. 应各加装注入管。To make and fit separate filling pipe to each tank. 应修复To be repaired. 应修复To be repaired. 四处补装,三处修复4 new hooks to be fitted; 3 hooks to bere-positioned. 应检查修复To locate leakage and repair. 应改装To be re-arranged. 应焊补To be re-welded. 应敲去重敷To be chipped off and re-laid. 应全部换新All to be replaced by a suitable type. 应全部换用合适规格羊角。All to be replaced by a type of suitabledimensions. 应检查并按设计要求修复To be examined and repaired to meet the designrequirements. 应适当提高。To be raised to a suitable height. 应解决To be remedied. 应解决To be remedied. 需改进To be remedied. 应换新To be renewed. 应换新To be renewed. 应换新To be renewed. 应换新To be renewed. 应改进To be remedied. 应检查修妥To locate leakage and repair. 应检查修妥To locate leakage and repair. 应焊妥To be welded. 应焊补To be re-welded. 应改装To be remedied. 应改装To be remedied. 应换新To be renewed. 应检查修妥To locate leakage and repair. 门修妥,挂钩换新Doors to be repaired to ensure free moving, door hooks tobe renewed. 挂钩座应移位至门的框架处Hooks to be re-positioned and attached directly to doorframes. 应修复To be repaired to ensure proper function. 应移位To be re-positioned. 应修复To be repaired. 应换新To be renewed. 建议改装为可开启的窗To be converted into open/close type..  应改装门钩Door hook to be converted into a suitable type. 应修复To be repaired. 应修复To be repaired. 应换新To be renewed. 应换新To be renewed. 应换新To be renewed. 应修复To be repaired. 应修复To be repaired. 应修复To be repaired. 应换新To be renewed. 应加包To be properly lagged with insulation. 应修复To be repaired. 应修理To be repaired. 应修理To be repaired. 应修理To be repaired. 应加装To make and fit complete with gaskets. 应检查修复To locate leakage and repair. 应补装To make and fit one scupper pipe. 应焊补并适当加强To be re-welded and suitably strengthened. 每一出口处应加装止回阀To fit non-return valve to each drain outlet. 约10平方米需换新To renew about 10m2. 应校正,并作适当加强To be faired and suitably strengthened. 应修补To be repaired. 应改进To be remedied. 应改进To be remedied. 应将甲板敷料除去后重敷甲板敷料Deck coverings to be removed where rusted, and to bere-lain after removing rusts from decks. 应修妥To be repaired. 应增设一只与原滤器并联的滤器To fir one more filter in parallel with theoriginal. 应在各分路管上设一调节阀To install one regulating valve in each branchpipe. 应修妥To be repaired. 应换新To be renwed. 应找出螺旋浆引起空泡腐蚀的原因并加以纠正(包括备用螺旋浆)To find out the cause of pittings fromblades and remedied (including spare propeller). 应在各分路上个设一截止阀One stop valve to be installed in each branchpipe. 应在各原动机的淡水冷却器系统最低处设一放水旋塞One drain cock to be fitted at the lowestpostion in each fresh water colling system. 应予换新To be renewed. 应予换新To be renewed. 应予换新To be renewed 应进行研磨To be fitted and ground. 应进行修理To be repaired. 应进行合理布置To be properly arranged. 应予换新To be renewed. 应予换新To be renewed. 应进行研磨To be fitted and ground. 应检查修复To be overhauled and repaired. 应予修复To be repaired. 应予修复To be repaired. 应进行研磨To be fitted and ground. 应予修复To be repaired. 应对活塞冷却水系统进行检查和清洁Piston cooling water systems to be overhauled andcleaned. 进行检查清洁Main engine fresh cooling water systems to be overhauled andcleaned. 应重焊To be re-welded. 管子割换一段To crop and renew one section of pipe. 应重焊To be re-welded. 应进行研磨To be fitted and ground. 应补敷绝缘材料To be properly lagged with insulation. 重新敷设绝缘材料To be relaid with insulation. 应消除舵机间的异常振动。损坏项目按要求修复 Abnormal vibration to be removed, and: 应予换新To be renewed. 应重新设计后换上To be renewed but subject to new design. 应换新To be renewed. 裂缝钢板应换新并作适当加强Cracked steel plates to be renewed and strengthenedappropriately, after repair, tanks to be tested fortightness. 修复后控制箱应重新布置To be repaired, after that, the control box to beproperly rearranged. 应换新All to be renewed. 应换新To be renewed. 应查明原因并解决To be checked and remedied. 应查明原因并解决To be checked and remedied. 应查明原因并解决To be checked and repaired. 应修复To be repaired. 应换新To be renewed. 应换新To be renewed. 应修复To be repaired. 应换新To be renewed. 应修复To be repaired. 应改装To be re-positioned. 应修妥To be repaired. 应换新To be renewed. 应查明原因并检修To check cause of leakage and remedy. 应改装To be re-arranged. 应换新To be renewed. 应修复To be repaired. 建议铺设防滑和耐油的绝缘地毯It is recommended that non-conducting mats beprovided. 应换新To be renewed. 应调换To be replaced by ballasts of proper type. 应换新To be renewed. 应调换Pump set to be replaced by proper type. 应解决To be remedied. 应配齐To be furnished by ship builder. 应换新To be renewed. 建议从助航仪器分电箱供电To be fed from the navigation aid distributionbox. 建议从动力分电箱供电To be fed from power distribution box. 应换新To be renewed. 应换新To be renewed. 应换新To be renewed. 应修复To be repaired. 应加装To be properly fitted. 应修妥To be repaired. 应修妥To be repaired. 应移位To be re-positioned. 应修妥To be repaired. |

船舶英语之报告部分 船舶行业分析报告

更多阅读

美的电磁炉各部分电路原理分析 电磁炉维修技法大揭秘

美的电磁炉各部分电路原理分析在此主要针对美的TM-S1-01A-A板(TM-S1-01A)(主芯片S007)电磁炉做详细讲解,主板各部分电路功能及其控制原理,以及常见故障的快速判断处理。??电磁炉电路图1、TM-S1-01A-A板(TM-S1-01A)(主芯片S007)

小学英语四年级期末测评质量分析报告(张赛艳) 江苏省学业测评四年级

小学英语四年级期末测评质量分析报告城北小学 张赛艳一、考试宗旨及命题特点本次期末考试由县教研室统一命题。听力占40%,笔试占60%。听力从听单词、短语逐渐地发展到听整个句子。内容体现了英语一级目标的基本要求,笔试从单词到句

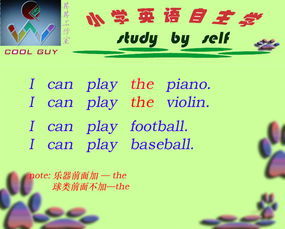

英语冠词部分语法详解 英语定冠词the的用法 定冠词the的用法口诀

英语冠词部分语法详解【复习目标】

PEP小学英语三年级下册期末试卷分析 pep三年级下册英语mp3

PEP小学英语三年级下册期末试卷分析城东小学 麻玉碧一、学生情况分析:我所任教的三年级有2个班。三(1)班参加考试的有57人,三(2)班参加考试的有56人。本次试题着重考查学生运用英语的能力,难度适中,比较切合学生的实际,提高学生的自信心。

新标准英语第一册教材具体内容分析转载 新标准英语教材分析

新标准英语第一册教材具体内容分析(转载)Module 1题目Greetings(问候)

爱华网

爱华网